Lean business:

A practical low-cost approach to increasing a business system’s capacity, effectiveness, and profitability by increasing current capability and resource utilization through the reduction of non-value adding activities (actions consuming time, resources, energy, and cash, yielding little or negative real return) providing intentional focus on those actions and activities that provide the greatest positive impact producing the highest tangible and sustainable return.

Solving business problems - Two approaches:

1. Innovation, applying the latest high-tech equipment and systems, typically at significant cost and risk

2. Lean, a highly effective and practical, low-cost approach utilizing current capabilities and resources

Both have their place, but lean provides the means to leverage the greatest amount of value-producing benefit from current capabilities and resources at little to no additional cost or risk.

Value focus:

A focus on the value-adding steps and processes in the value stream that provides the straightest and shortest path (least time and resource consumption) through the whole-system value stream, from start to finish. A value focus identifies all steps, movements, wait time, space, (waste) that consume time and resources but add no value to the product or service provided.

There is often tremendous opportunity for tangible gain with current resources and capabilities by reducing non-value-adding activities and deploying the freed-up time and resources to real value-adding actions.

Value-add:

Any, and all, actions and things that add tangible value - what a customer is willing to pay for - to the product or service being provided

Waste – Non-value-adding:

Any, and all, actions and things that consume resources -time, materials, effort, cash – but create no additional value to the product or service provided. Eliminating waste, frees up time and resources that can be deployed to value creating actions, increasing productivity and reducing unproductive actions and demands.

Value stream:

The flow of actions and processes that take place from the start to finish of any product, service, or cycle: prospect – appointment – sale - order entered – process/make – ship – invoice - receive payment

There is a value stream, also, within each component of the complete cycle. There are opportunities at -the whole system level as well in each individual component to capture value creating opportunity with the least consumption of resources.

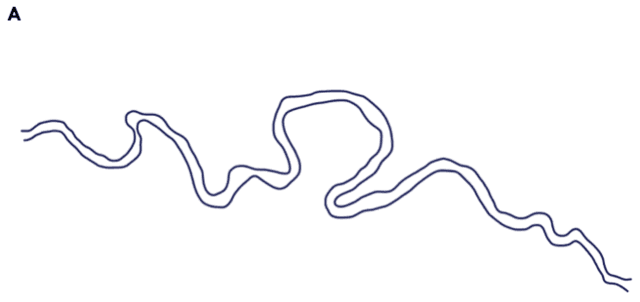

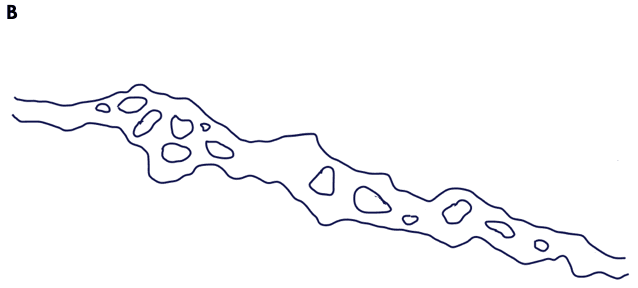

Flow Illustration – Work Flow & Information Flow:

Unleash hidden capacity and slash unnecessary costs and effort by straightening and shortening the path and removing hurdles and barriers to your work and information flow.

Meandering

- Long

- Slow

- Variability

- Difficult to track

- Difficult to coordinate

- Hazards

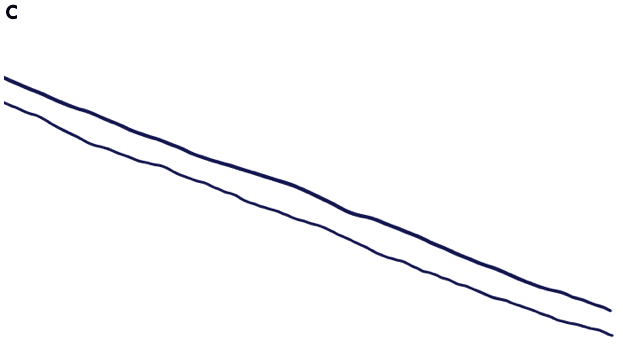

Straighter path full of hazards

- Bottle necks

- Stress, churn, risk

- Unpredictable

- Difficult to track and coordinate

- Safety & quality risks

Straight & unrestricted

- Shortest distance

- Least resistance

- Less stress, strain, risk

- Few variables

- Greater predictability

- Greater safety

- Clear visibility to see normal from abnormal

- Fewer errors & rework

- Greater velocity

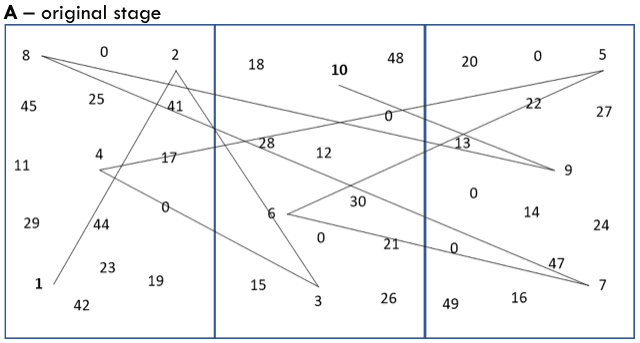

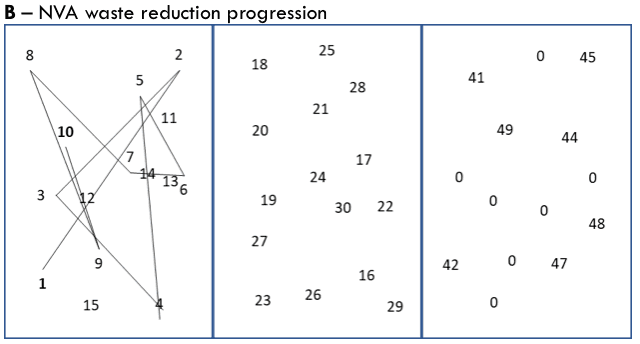

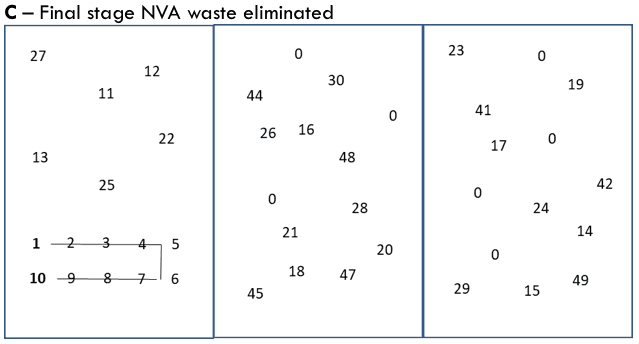

Distance, Time, Space, Labor, and Cost Reduction by Eliminating Non-Value Adding Activity (Waste)

(In a 10 – Stage Process)

Consider each number 1-10 as a value-adding stage in a complete production process (can apply to any process such as paper flow). All movement and wait time between stages is non-value adding (NVA) or waste that consumes time, labor and space. With a focus on eliminating NVA or waste, significant productivity increases, and cost, labor, and floor space reductions can be achieved at little or no additional expense.